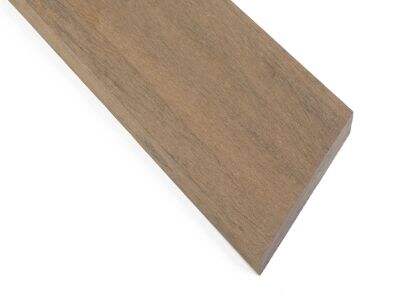

If you would like to have your WPC (Wood Plastic Composite) products to keep long lasting as well as more durable and beautiful, you definitely should consider our Co Extrusion Technology. Our superior performance is made possible by our innovative technology, taking the quality of WPC products to a whole new level. By adopting such technology you can make better quality WPC products and distinguish yourself from your competitors.

Increase Long Time Quality with The Second Processing Step Co Extrusion of WPC Profiles

Co Extrusion Technology adds a protective layer to the surface of WPC products during manufacturing. This layer forms a protective barrier against scratches, stains, body oils and other signs of wear. Increasing the longevity and functionality of your WPC products You can add years to the life of any WPC product to help it keep looking its best by protecting surfaces. This power can enable you to sell a premium, top quality WPC decking product that other sellers will struggle to match.

Protect your WPC Products from wear and tear with coextrusion technology

Jfwpc Co Extrusion Technology protect your WPC products from the effects of UV and usage, will not rot, splinter, split or warp. This extra layer of protection not only prevents products from being dinged or damaged, it also makes them easier to clean and keep beautiful. With panel wpc products that use Co Extrusion Technology, they stay new for longer ensuring you save money and time in the long run having to do repairs or replacing them.

WPC Surfaces Enhanced with Co Extrusion Technology That Precisely Applied Everyday Stand Out From Your Competitors

In today’s competitive marketplace, you need to stand out from the crowd. And with Co Extrusion Technology integrated into your production line, you will be able to provide high performing WPC products that overshadow the competition. The advanced surface oxidation CO EXTRUSION technology makes the surface of WPC pickling copper while its anti UV performance has reached 5 level grade then wood texture pattern will not change because of solarization it becomes novel and beautiful which guarantees the quality must be good It is originally co extrusion. Adopting such technology is a shrewd business move in order to stay before the game, and retain your treasured customer base.

Invest in WPC Surfaces Using Co Extrusion Technology for Longevity

When you invest in Co Extrusion Technology for your WPC products, you are investing in durability. With this technology, your WPC surfaces will remain intact and vibrant for the life of your deck. This is not only good for your customers because of high-quality products, but also good for your business with less maintenance overhead and a better customer experience. Select Jfwpc for Co Extrusion Technology, you can deserve.

Enhance WPC profiles with Co-extrusion Decorative Layer/Coating-Tech Profile.

With Co Extrusion Technology The Quality of Your WPC Increases Drastically. This advanced technology gives a value to your products and is guaranteed for life time. You will have satisfied customers, as your Outdoor WPC Decking products are beautiful and durable, they remain satisfied for a long time and will recommend you positively to others. Select Jfwpc for all your Co Extrusion Technology with needs and lift your WPC to a different level of quality.

Table of Contents

- Increase Long Time Quality with The Second Processing Step Co Extrusion of WPC Profiles

- Protect your WPC Products from wear and tear with coextrusion technology

- WPC Surfaces Enhanced with Co Extrusion Technology That Precisely Applied Everyday Stand Out From Your Competitors

- Invest in WPC Surfaces Using Co Extrusion Technology for Longevity

- Enhance WPC profiles with Co-extrusion Decorative Layer/Coating-Tech Profile.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

PL

PL

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

MS

MS