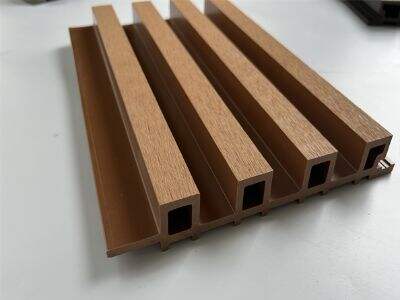

Through the extrusion of different materials, manufacturers can form Integral strength in top decay The outer later of a panel prevents from damage. This new process is proving very attractive as it offers a low cost solution for enhancing the quality of WPCs panels.

How co-extrusion enhance the durability of WPC Panels?

Layer of co-extruded WPC panels - Co-extrusion increases the durability of WPC boards by providing them with a strong, scratch resistant, and UV-resilient layer. This protective cover serves as a shield, protecting your device from damage caused by daily wear and tear. Consequently, WPC panels with co-extruded surfaces have enhanced resistance and a longer life span than standard WPCs, which require regular maintenance to prevent them from ageing. This exclusive durability makes them perfect for all high traffic areas and can withstand any climate condition, whether is dry or humid.

In addition, the surface design is also co-extruded which makes it not just surface-free but also easy to add the texture and color according to clients' demands. This makes not only for nicely looking panels, but also an additional guard on them. For instance, a wood grain pattern can be embossed into the surface of WPC panels, which gives an appearance similar to natural wood while greatly increasing its resistance to wear. This diversity of design options allows co-extruded WPC profiles to be widely used.

What's more, co-extrusion serves to bolster the overall durability of WPC panels by protecting them from the elements. The result is a wpc panel for wall that will not warp, crack or fade like other decking products making WPC ideal for the garden. Co-extruded WPC profiles are the most durable types of outdoor flooring; they can last up to 30 years.

Where to source Premium Co-extruded WPC Boards?

When you want to buy high-quality co-extrusion WPC panels, jfwpc is your wood plastic panel choice. We are best Wood Plastic Composite Co-Extrusion High class Great Weather Resistant factory, who can offer high quality Wood Plastic Composite Co-Extrusion High class Great Weather Resistant for you! You can locate our products at top home improvement stores, online retailers and via our network of authorized dealers. We pride our selves on quality and service guaranteeing you the best value for the money when choosing jfwpc as your projects wood source.

Why you choose co-extruded WPC panel for your projects?

Co-extruded WPC panels have a few major features of merits versus other conventional wood and plastics. Co-extrusion Co-extrusion involves two or more materials being pressed together to make a stronger and more durable product. In wpc panel design, the outer layer is co-extruded with a seal coating- making it more surface hard and so that the color will not go away over the years. This means that your project will be completed in the highest glory and s will take care of your needs over the many years to come without having to stain or refinish the project frequently. In addition, co-extruded WPC panels are also green and may be recycled as an alternative that exactly does not contradict the principles of the most ecologically friendly consumers.

Are co-extruded WPC deck panels worth the money?

There is no way to resist style and strength that co-extruded WPC panels offer. The expenses can be slightly higher than the traditional materials, but the final cost-efficiency is significantly higher. co-extruded WPC boards, have very little maintenance requirements and are convenient to maintain, which save time and money in the long term. Moreover, you also get a hard surface that won’t scratch or wear, and realistic wood plans that will not appear as an imitation, when subjected to co-extrusion, and the fact that you do not need to use your time in sanding, staining or painting. Overall, co-extruded wpc panel is a decent investment to persons who require flawless and natural wood-like beauty with minimum maintenance.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

PL

PL

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

MS

MS